Worker aghast at shoddy work on Fukushima radioactive water storage tanks

By MASAKAZU HONDA

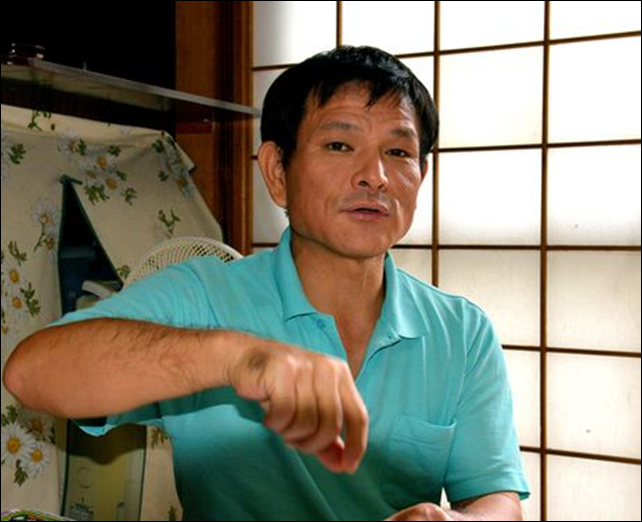

4 January 2014 URUMA, Okinawa Prefecture (The Asahi Shimbun) – Yoshitatsu Uechi recalls with disgust the disregard for worker safety, the makeshift plans and the cost-cutting measures, including the use of adhesive tape on key equipment, at his job last year. He said an emphasis on saving time and expenses was clear when he helped to build storage tanks for radioactive water accumulating at the site of Japan’s worst-ever nuclear accident. “I couldn’t believe that such slipshod work was being done, even if it was part of stopgap measures,” Uechi told The Asahi Shimbun. He was one of 17 workers from Okinawa Prefecture who were sent to the crippled Fukushima No. 1 nuclear power plant on June 28, 2012. The 48-year-old from Uruma said he worked on foundations and storage tank assembly between July 2 and Dec. 6, 2012. He said he was sent to various places at the site, including “H3,” an area now known as the spot where high radiation levels have been found due to leaks of radioactive water from the storage tanks. The leaking tanks are just part of the problem of contaminated water that continues to build up and leak into the ocean from the plant. […] Workers were told to keep away from the radioactive water storage tanks, which had high radiation levels, even on the outside. “I wore a raincoat even on sunny days to block the radiation when I had to go near highly radioactive water,” Uechi said. His seasoned colleagues told him that the use of adhesive tape was one of the makeshift measures devised on the site to deal with the sharp increase in the stockpile of radioactive water. But he said he was surrounded by signs of shoddy work to slash costs and time requirements. For example, wire nets were used instead of reinforcing bars during the placement of concrete for storage tank foundations. And to save on the sealing agent used to join metal sheets of the storage tanks, waterproof sheets were applied along the joints inside flange-type cylindrical tanks. Some of these tanks were later found to be leaking radioactive water. [more]

Worker aghast at shoddy work on Fukushima radioactive water storage tanks